Grooving

It is done with a saw or cutter.

The system decides what to do.

The cutter is used:

- if the slot width is larger than the default cutter diameter

- with "quarters" - grooves with 0 indent from the edge.

Groove types: open - made after edging, closed - made before edging.

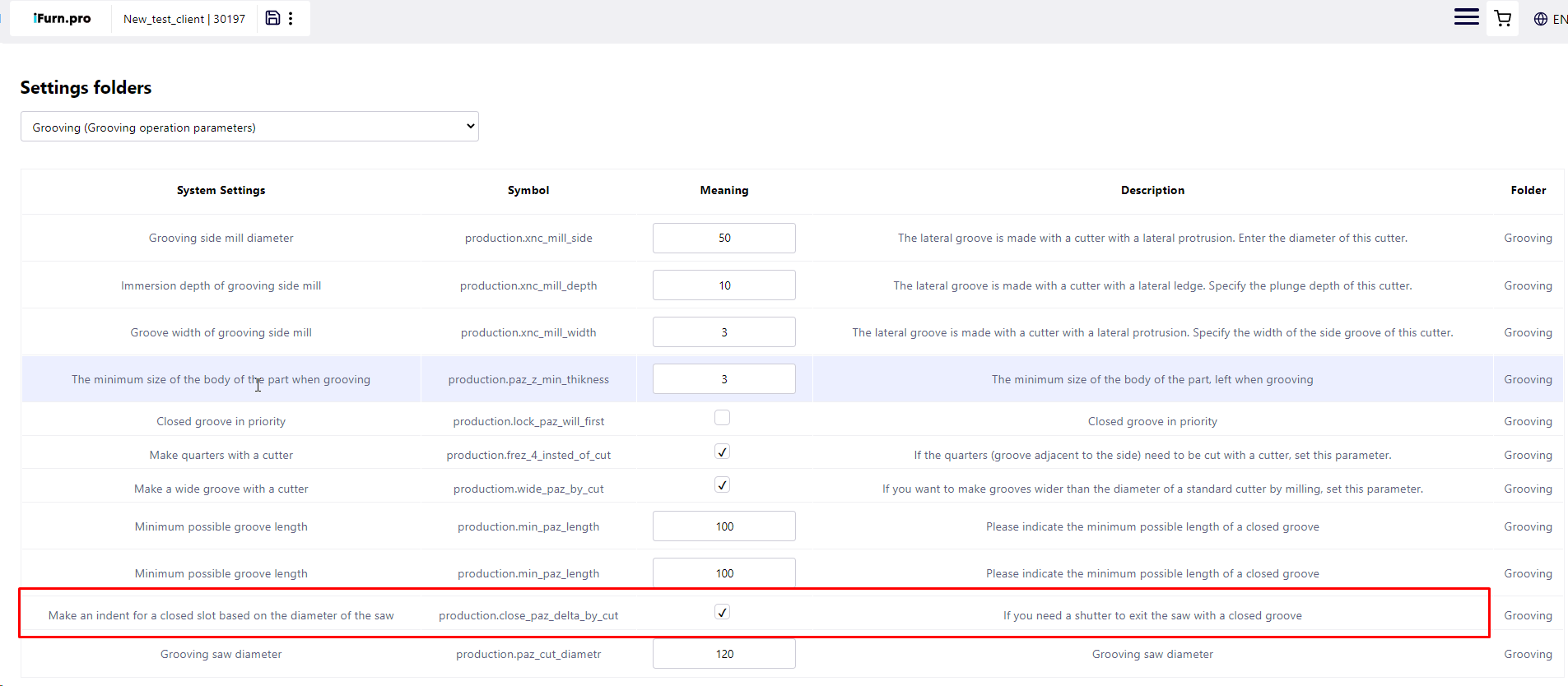

If a closed slot is being made with a saw (the slot width is smaller than the cutter diameter), when setting the desired parameter, the entry and exit point of the saw will automatically be shifted so that the saw does not go further than the desired one. Example: if the saw has a diameter of 120 mm, the exit point is set to 50. The point of 50 mm is the location of the center of the saw, respectively, the real cut will be further.

The system automatically adjusts the entry and exit so that the saw does not touch the material further / closer than the specified values.

Keep in mind that on the part it is worth making all the grooves open or all closed. In a mixed version, production will be very difficult or impossible in principle.

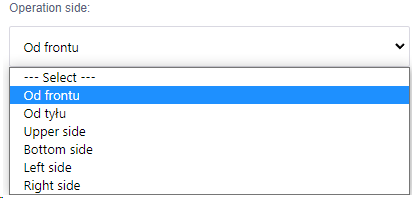

The side of the groove, like the hole, is set on 6 sides.

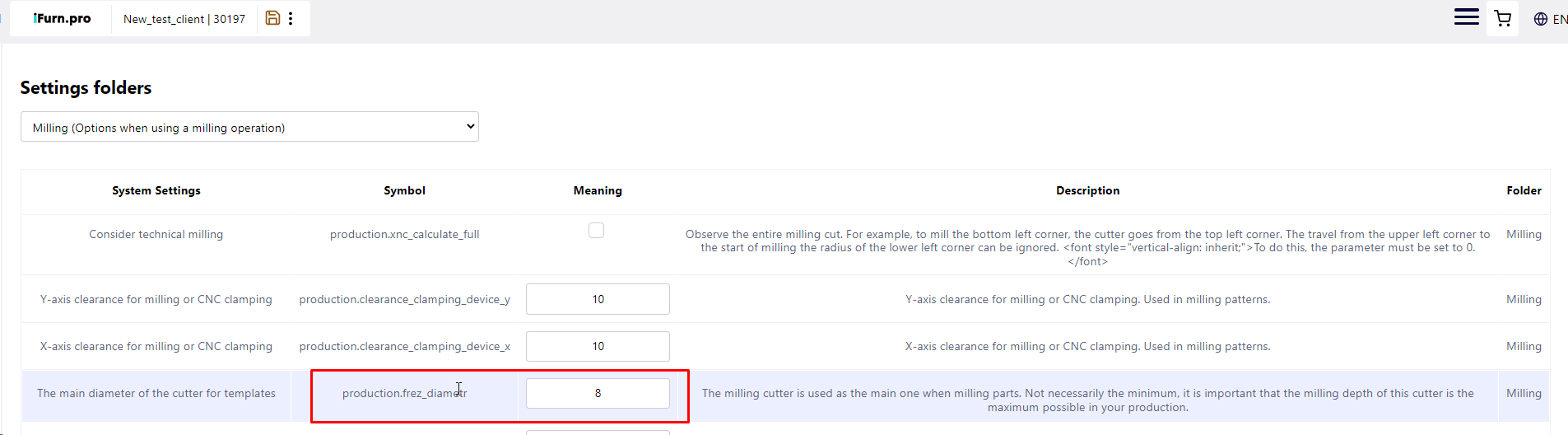

End grooves are made with a cutter. The manufacturing company in the admin panel sets the parameters of such a cutter, and when the program is uploaded, the groove will be recalculated into milling.

The furniture manufacturer sets the settings in the parameters.

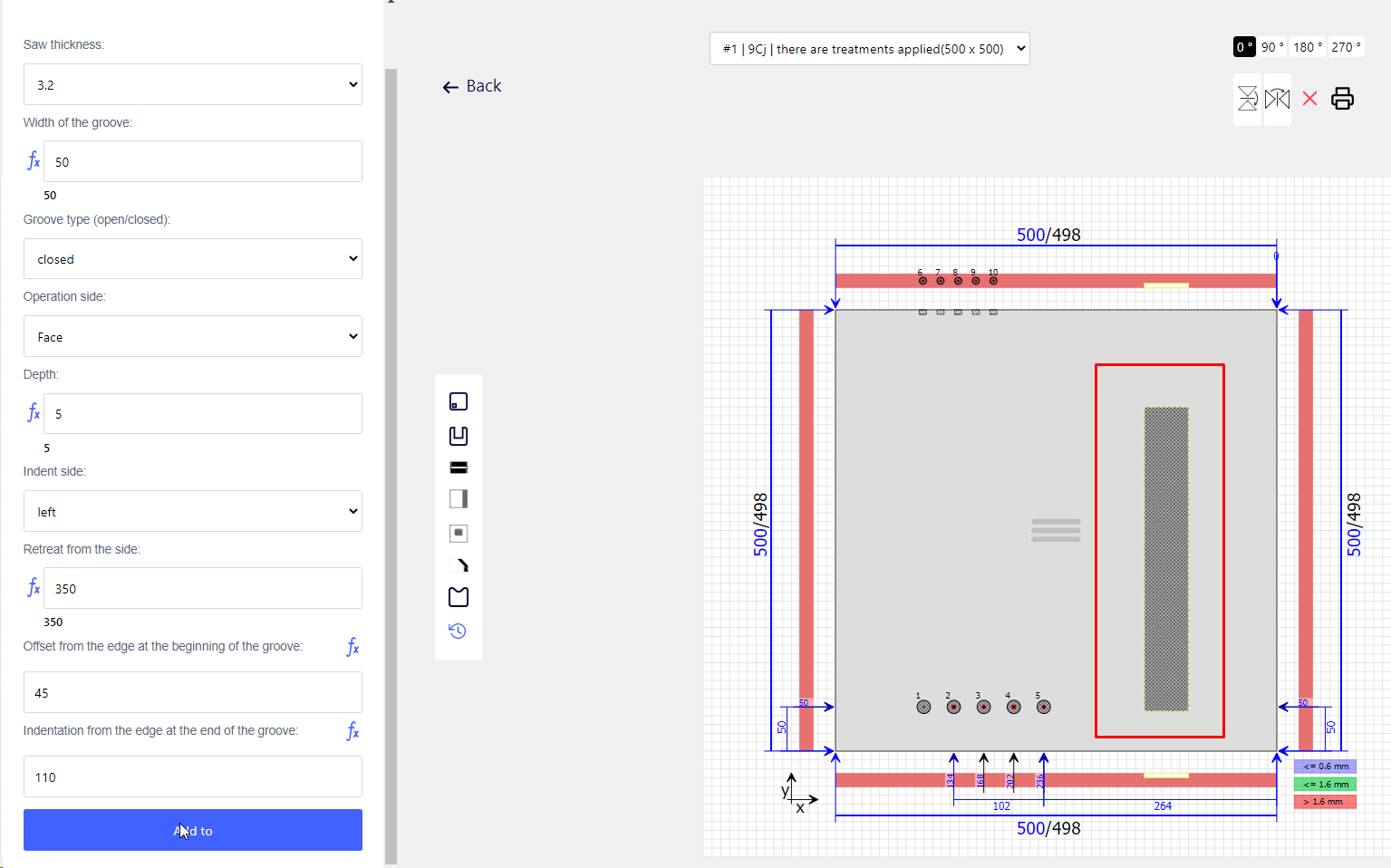

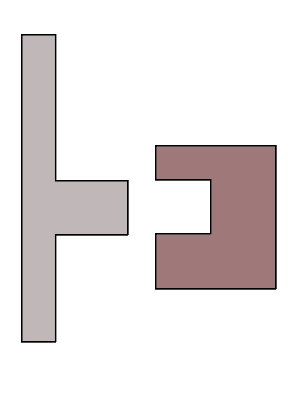

The groove is set by the parameters:

• From which side we retreat (overall dimensions)

• Distance TO THE EDGE of the groove.

• Grooving width

• Grooving depth

• Blade thickness

• Indents from the edges (closed groove)