End processing, edging

The end processing for board material and glass differs from each other:

Plate material is processed by an edge. Also, slab material can be processed by cutting the end at a certain angle. In this case, an indent from the edge of the part to the cut is possible.

The edging of the slab can be carried out with an edge that should be wider than the slab itself. The allowable difference between slab thickness and edge width is determined by the Service Provider.

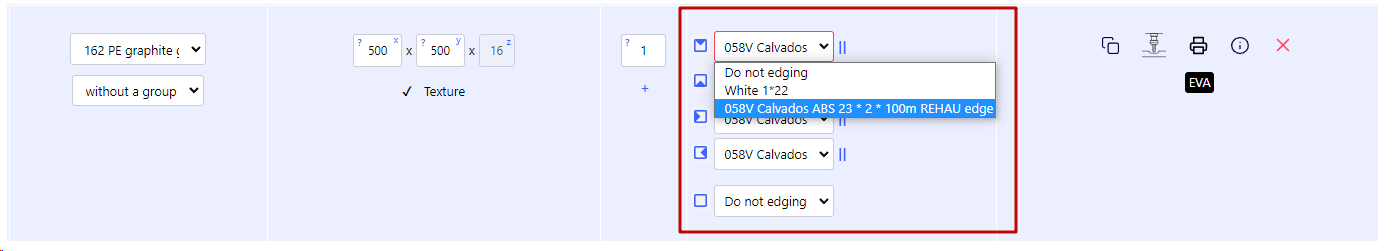

Edging can be set in the full detailing input mode:

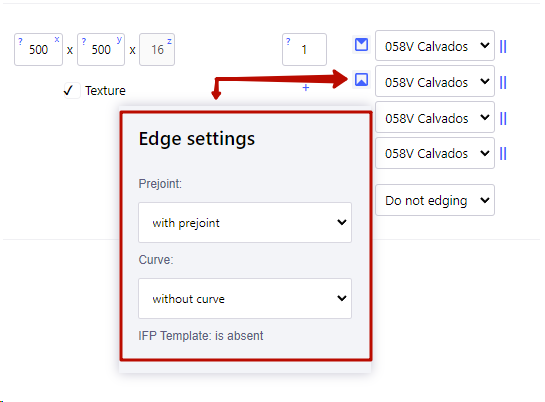

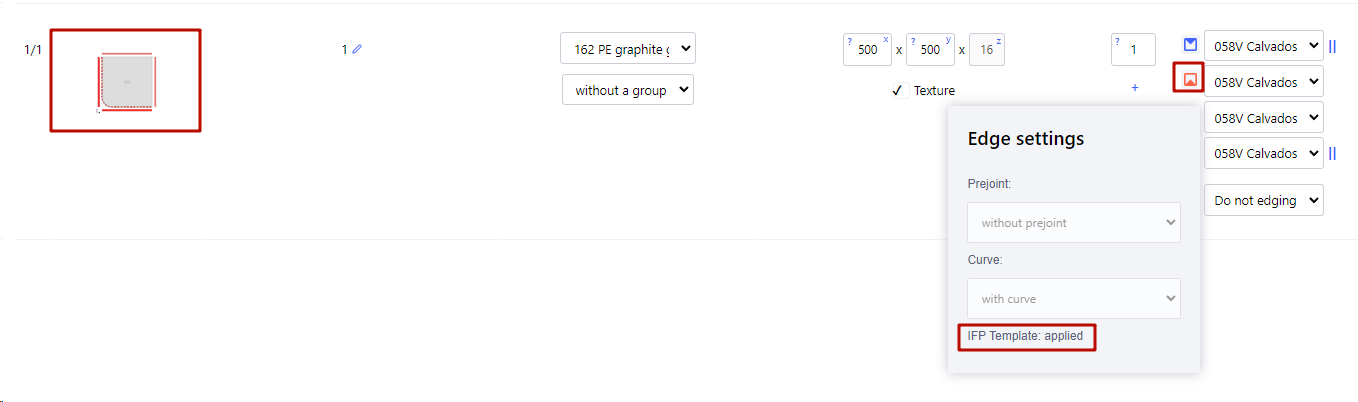

To set the joint and/or side curvilinearity, click on the symbol:

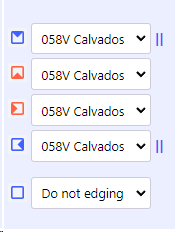

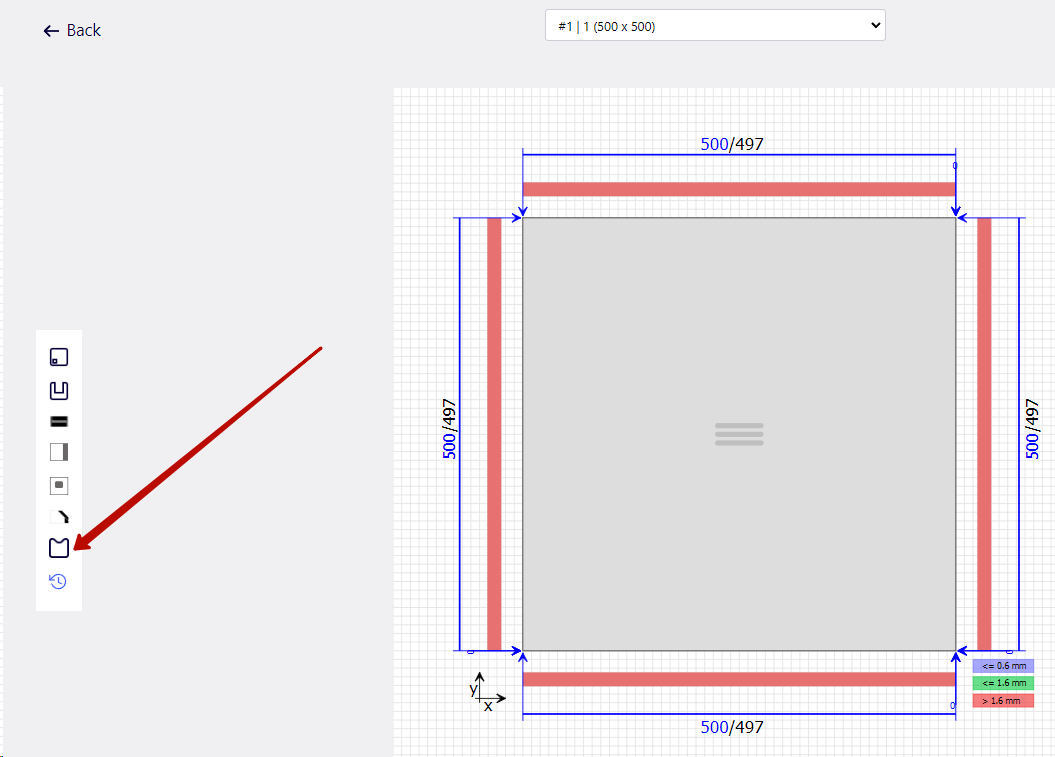

Curvilinearity also means manual edging. In detailing, it is easy to see the types of side processing:

The upper side of the part is machined by hand, without jointing (no blue sticks on the right). The underside of the part is machined with a jointer, machine without manual/curvilinear machining.

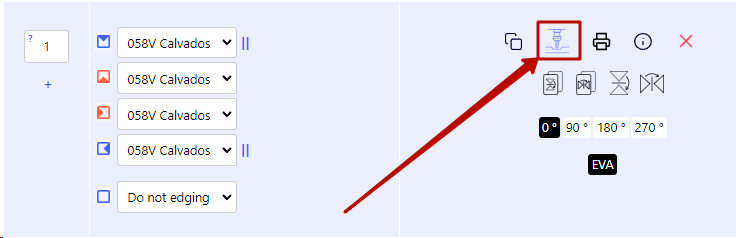

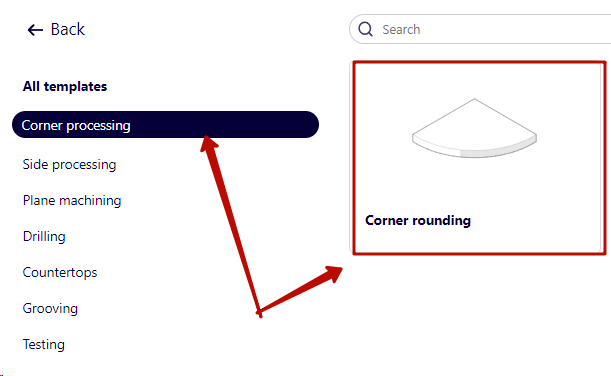

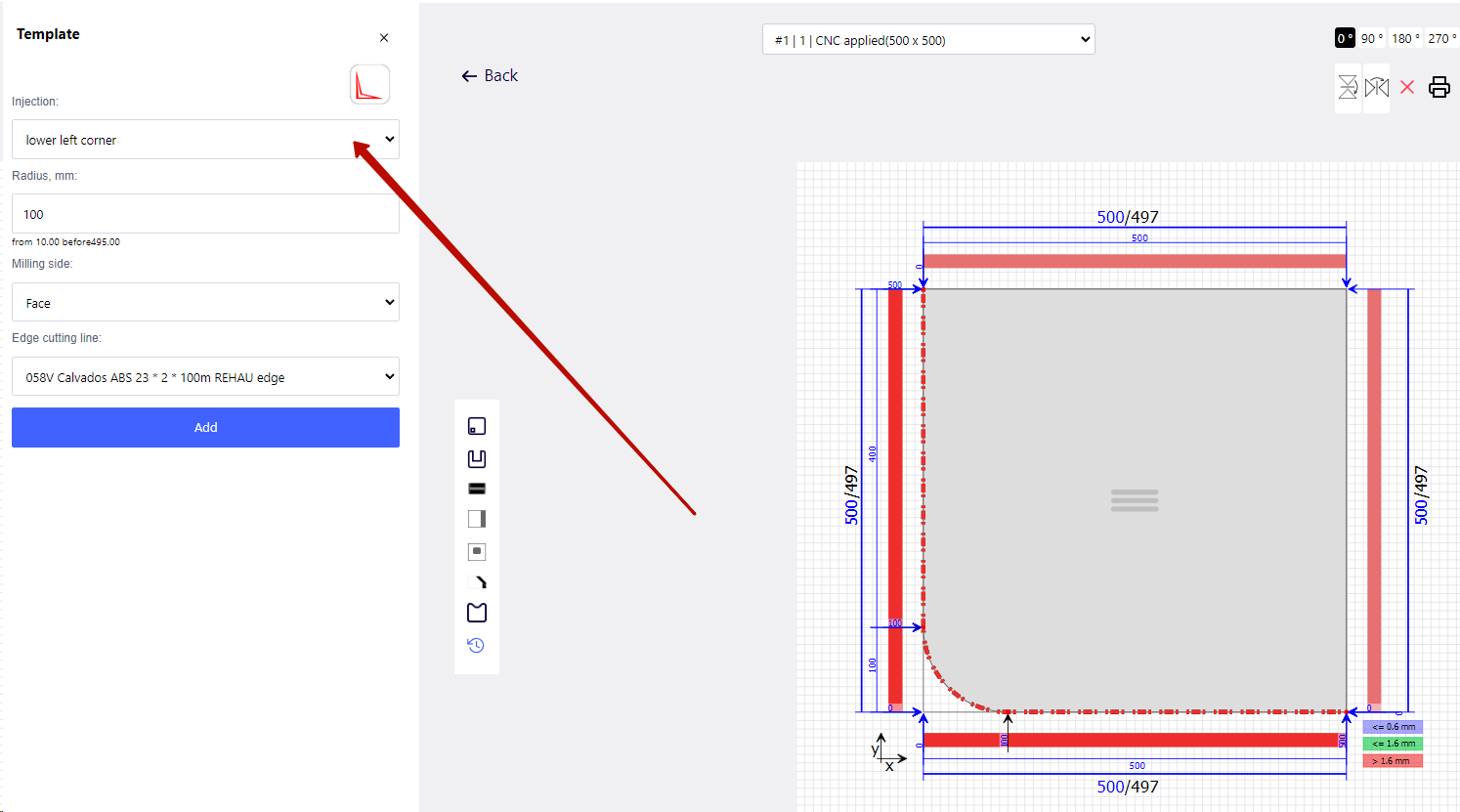

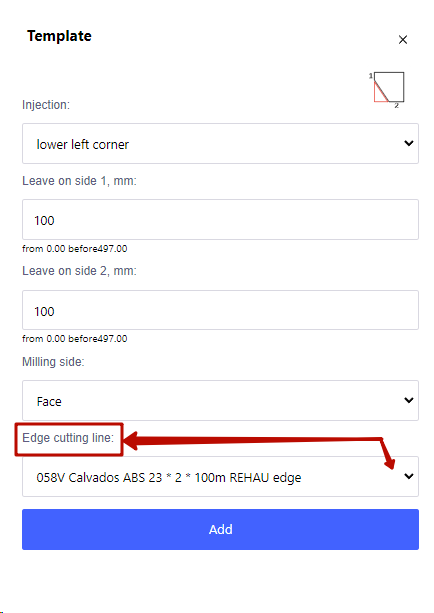

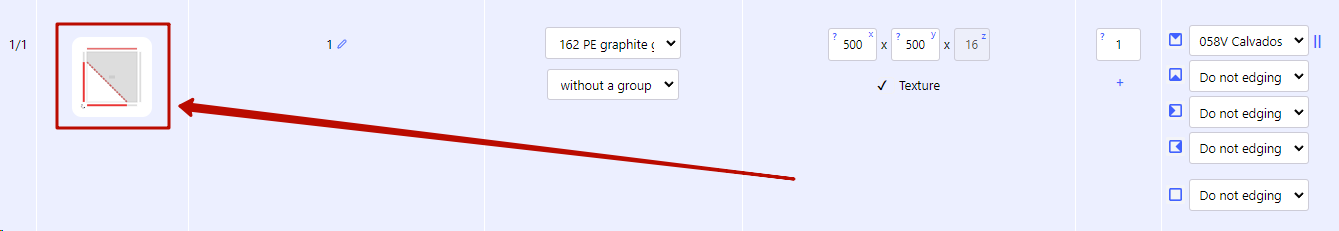

Curvilinear machining is set automatically when using the iFurn milling template:

The system will not allow you to manually change the joint and curvilinearity on the sides that are closed by the template. If you have imported a framing contour, you can manually change the joint and curvature for either side.

If you only need to bevel a milling contour (cutting a corner for example), you can use this option in milling:

IMPORTANT! If you specify both the edging of the sides and the edging of the milling cut, the services will be doubled in the cost estimate.