Drilling

The operation of the additive and drilling is carried out on 6 sides of the part. Holes can be made deaf (no outlet) and through (through parts). For through and blind drilling, different drills are used.

When unloading drills on machines, the system automatically corrects:

- depth of through holes (regardless of user entered, adjusted to material thickness + through drill diameter)

- drilling depth for confirmation (through 7 mm). If countersinking is detected, it is corrected for countersinking parameters

- depth of through drilling from the reverse side (if it is established that the machine can only drill to a certain depth from the reverse side of the part, the system divides drilling into 2 - from the reverse side to the possible depth and from the front, additional drilling of the remainder)

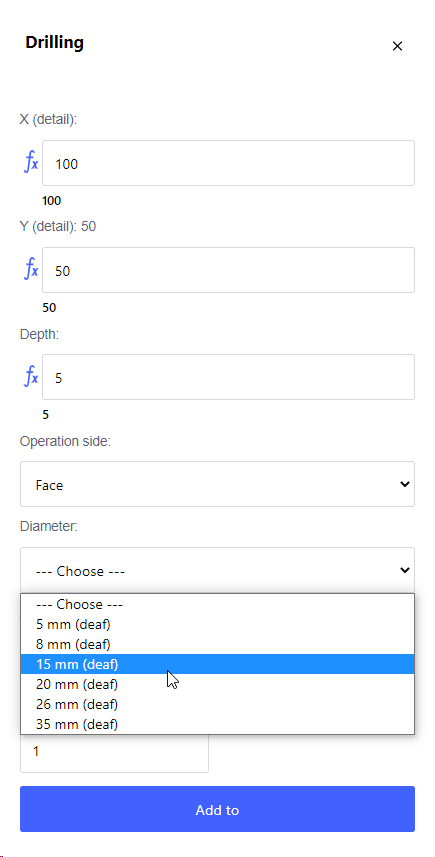

Drilling diameters can be selected based on the depth of drilling and the availability of tools from the manufacturer. A furniture manufacturer installs its tools in a personal account.

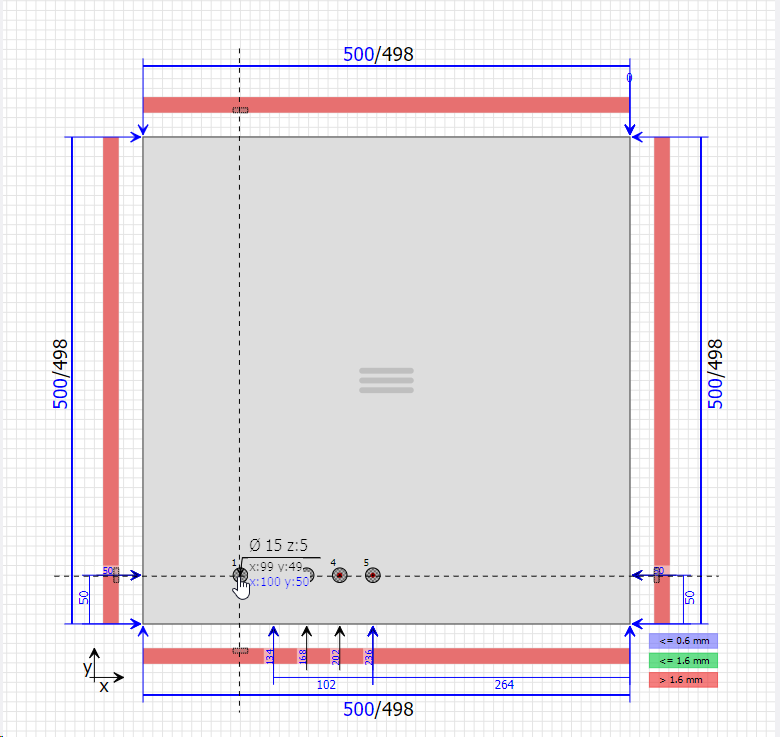

After adding a hole, you can see its parameters by hovering over it with the mouse. If you click on the center of the hole, the parameters of the hole will be visible all the time.

In the parameters of the hole, both saw and overall parameters of the hole are visible.

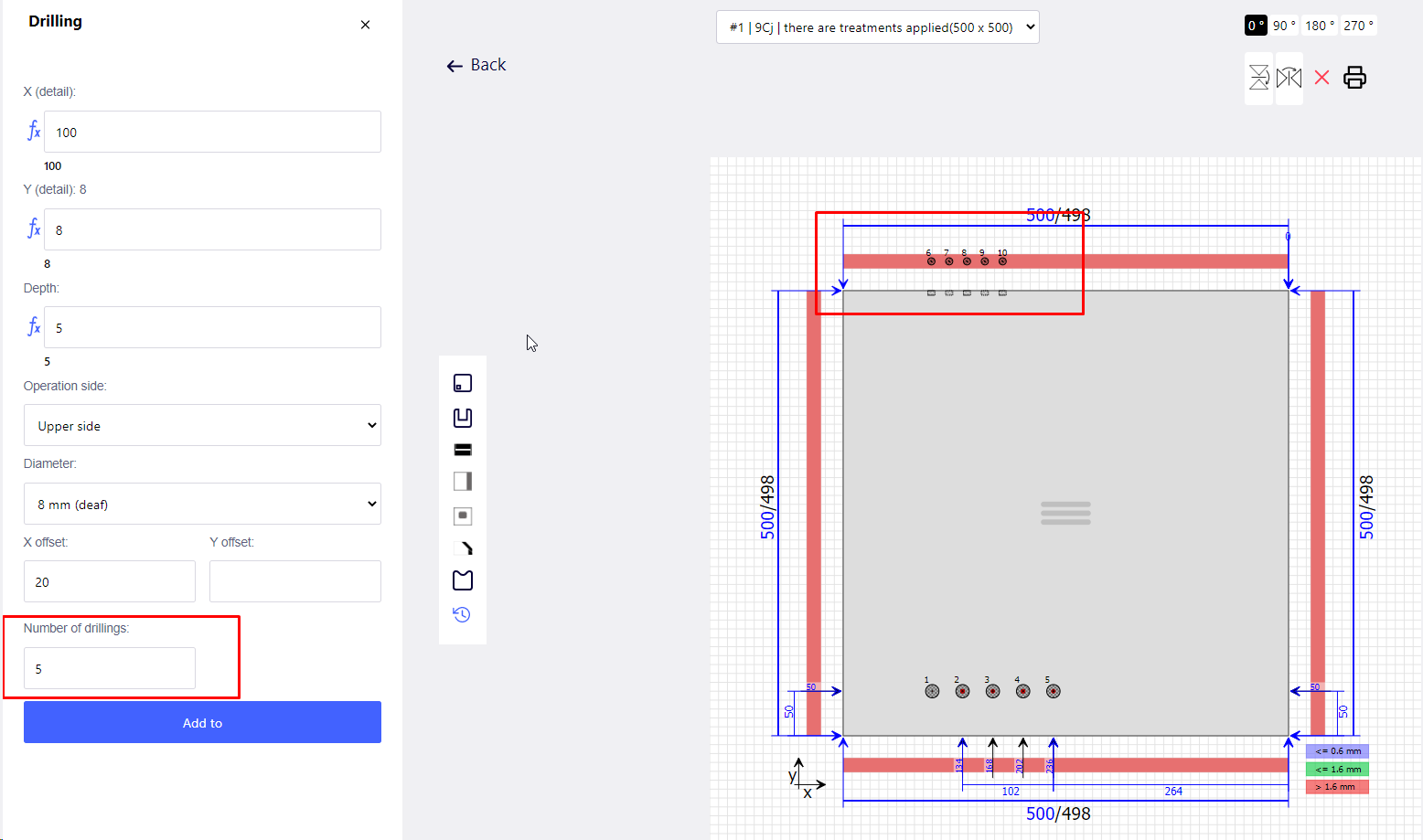

The X and Y of the end hole are marked according to the drawing of the end on the screen.

You can enter an offset in X or Y, the number of holes and the desired number will be created.